Discover our industrial automation solutions

NEW

NEW

WELDING METHOD MIG/MAG / TIG PRODUCT DIMENSIONS 880 × 1280 × 2500 mm PLC SYSTEM 7” PLC Control System WELDING TYPE Fishmouth / Sleeve Welding BED SYSTEM Elevating, horizontally movable, removable V-bed WORKING RANGE Distance Between Tack Beds: 530 mm AXES A and Z axis WELD OVERLAP Available WELDING MOUTH DIAMETER 200 mm OSCILLATION Vertical oscillation available PNEUMATIC TACK PRESSING Adjustable pressure The fishmouth welding automation system offers a practical solution as a unique machine in its class in terms of working principle. It is designed to weld the fishmouth-shaped cutouts made on pipes. Simply mark the top and bottom points, set the speed and oscillation distance, and press start. Both single-sided and double-sided outlets can be welded. With the specially developed quarter-turn overlapping welding method, leakage risk and poor weld appearance are eliminated. Product features are as listed above. With the help of the table lift system, the product can easily be raised to the desired height. After positioning the product, it can be easily lifted from the fixture using the pneumatic tack unit.

View Details NEW

NEW

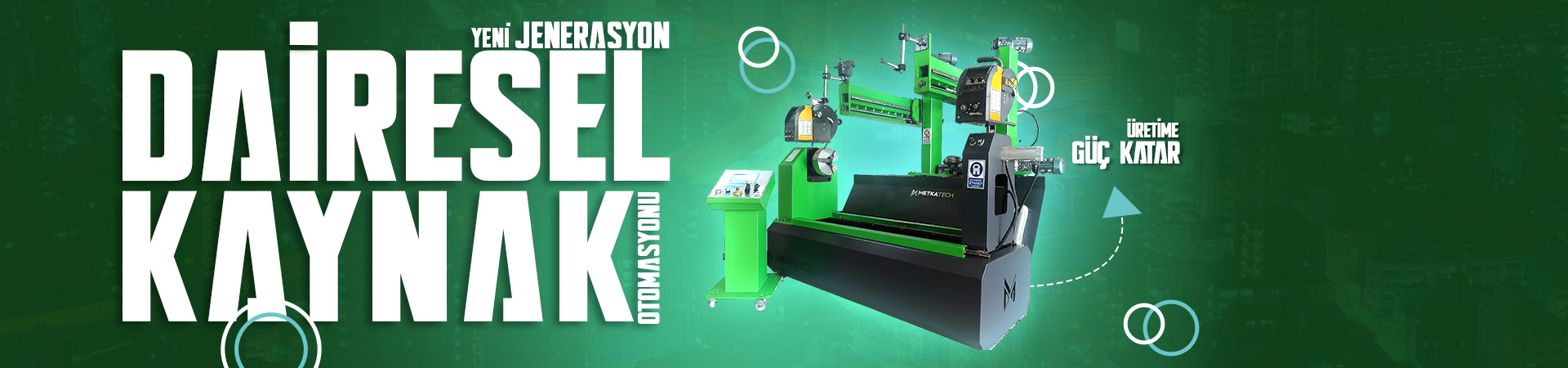

Circular Welding Automation – Technical Specifications Turning capacity: Ø 0–100 / 400–160 cm Rotation capability for workpieces: 100–400 cm length 250 mm 3-jaw chuck 20 mm linear guideway and carriage set (on all axes) Torch holder adjustable for automatic welding torch Pneumatic center punch (replaceable shaft input) – pointed center Oscillation system: Available Loading system: Mechanical center support alignment Welding Modes: Circular welding Welding Methods: TIG / MIG-MAG / Submerged Arc Welding (SAW) Operating Voltage: 380V 4 Axes (X–Y–Z–A) Rotation Motor: 12 Nm stepper motor with reducer Feeding Motor: AC motor with reducer Y–Z–X motion motors: 0.25 kW AC motors with reducer PLC Screen: 7" PLC + external PLC unit PLC Screen Type: Touchscreen AC transformer for stepper motors Electrical panel designed according to CE standards with filtered ventilation Joystick movement control for 3 axes Mobile wheeled control unit for PLC screen and control panel Machine Color: RAL6018 / RAL7016 Custom Manufacturing Options Product dimensions are flexible. Turning distance between chuck and center can be produced as 100 / 200 / 300 / 400 cm, depending on your requirements. The machine can also be manufactured with single-torch or dual-torch axis configuration.

View Details NEW

NEW

NEW

NEW

NEW

NEW

Technical Specifications Maximum Pipe Diameter: 400 mm Distance Between Centers on Support Bed: 500 mm Torch cable routed internally through the pipe Detachable pipe support and pointed pneumatic centering unit V-type support bed Height-adjustable AC motor-driven rotary table with reducer Adjustable center positioning for spot/centering unit Manually adjustable vertical torch positioning arm Manually adjustable horizontal torch positioning arm Rotation motor: Stepper motor with reducer Dual-joystick manual control system 7” Touchscreen PLC AC-powered transformer for stepper motor supply Electrical panel designed according to CE standards Filtered panel ventilation system Mobile wheeled control unit for PLC screen and operator panel Machine Dimensions: 865 × 1275 × 2500 mm Machine Color: RAL 6018 / RAL 7016

View Details NEW

NEW

Technical Specifications Maximum Diameter: 850 mm Maximum Length: 1200 mm Copper Backing Plate: 6 mm, spherical slotted design Sheet Thickness Range: 0.6 – 10 mm Copper backing plate with water circulation cooling system + fan unit Rear support stopper for workpiece positioning Vertical axis movement driven by reducer-equipped stepper motor Oscillation System: Available Copper-based support beam: 125 × 80 mm Clamping Jaws: Steel body with copper-tipped surfaces Pneumatic clamping system for jaws Welding Methods: TIG / MIG-MAG / Submerged Arc (SAW) Elevator (lifting) system: Optional Machine Color: RAL 7016 / RAL 6018

View Details NEW

NEW

NEW

NEW

Maximum Diameter: 1600 mm Maximum Length: 2100 mm Copper Backing Plate: 6 mm, spherical slotted design Sheet Thickness Range: 0.6 – 10 mm Copper backing plate with water circulation cooling system + fan unit Rear support stopper for workpiece positioning Vertical axis movement driven by reducer-equipped stepper motor Oscillation System: Available Copper-based support beam: 125 × 80 mm Clamping Jaws: Steel body with copper-tipped surfaces Pneumatic clamping system for jaws Welding Methods: TIG / MIG-MAG / Submerged Arc (SAW) Elevator (lifting) system: Optional Machine Color: RAL 7016 / RAL 6018

View Details NEW

NEW

NEW

NEW

NEW

NEW

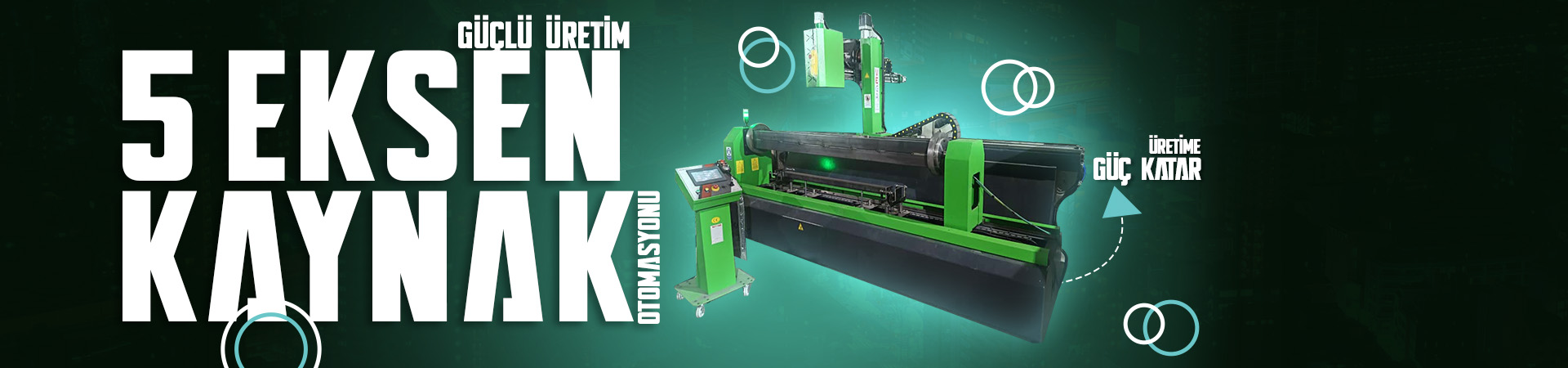

• Turning Capacity: Ø1600 mm • Rotating Length Capacity: 3000 mm • Dual Torch Connection Axis: Each torch has 3-axis movement capability + 2-axis oscillation system • Chuck: Ø250 mm • Linear Guide & Carriage: 25 mm or 20 mm on all axes • Torch Holder: Adjustable according to automation torch • Hydraulic Tack (Point Press): Available (Sharp Tack Type) • Oscillation System: Available (2 units) • Loading System: Hydraulic loading with angled ramp • Welding Modes: Circular welding • Welding Methods: TIG / MIG-MAG / Submerged Arc (SAW) • Operating Voltage: 380V • Axes: 4-axis (X-Y-Z-A) + two independent X-Y-Z sets • Rotation Motor: 12 Nm step motor with gearbox • Travel Motor: Geared AC motor for linear welding • Y-Z-X Travel Motors: 0.25 kW geared AC motors • PLC Screen: 7” PLC + external PLC unit • PLC Interface: Touchscreen • Power System: AC transformer for step motors • Control Cabinet: CE compliant, filtered cooling ventilation • Movement Control: Joystick control for all 3 axes • Machine Color: RAL 6018 / Black / Anthracite Grey ADDITIONAL FEATURES • Side-lifting hydraulic loading table, aligning the product with the chuck axis • Hydraulic tack pusher enables dome-forming / bulging operations MATERIAL SPECIFICATIONS • Lower bent body sheet: 5 mm • Chassis profiles: 80 × 80 × 5 mm • Rear support columns: 10 × 250 mm • Moving axis connection parts: 20 mm • Chuck body: 10 + 20 mm • Tack unit: 10 mm • Slide carriage moving parts: 20 mm • Hydraulic lifting components: 15 mm • Loading ramp lifting capacity: 2 tons

View Details NEW

NEW

NEW

NEW

NEW

NEW

NEW

NEW

NEW

NEW